An insulator is a material that does not conduct electrical current. Insulating material include paper, plastic, rubber, glass and air. Vacuum is also an insulator, but is not actually a material. Most electrical conductor is covered by insulation. Magnet wire is coated with an extremely thin layer of insulation so that more turns or larger wire may be used in the winding of transformer etc. Insulators are generally rated at hundreds of volts, but some that are used in power distribution are rated as high as hundreds of thousands of volts. Insulators support and/or keep electrical conductors from making unintended contact with each others.

Stephens Gary (1666-1736) demonstrates that the static charges of electricity can be conducted by some materials “Between 1729 and 1736 he (Stephen Gray) gave the results of many experiments which showed that the electric virtue of a tube of glass that had been excited by friction could be conveyed to other bodies thereby giving them the ability to attract and repel light bodies. Gray and a friend, Jean Desaguliers, conducted experiments which showed that objects such as cork, as far as eight or nine hundred feet away, could be electrified by connecting them to the glass tube with wires or hempen string. They found material such as silk would not convey electricity. They discovered distant objects could not be electrified if the transmission line made contact with earth. The line for transmission was suspended by silk threads to prevent contact with the ground. It was found that metal objects held in the hand and rubbed showed no signs of electrification. However, when mounted on a non-conductor, they became electrified. Gray realized that somehow the earth was responsible for conducting electrical charge away from the body. After this realization Gray found he could electrify any material on earth by friction. He even went as far as to suspend pupils of the house by cords and electrified them, sometimes even drawing sparks from the human body.”So Gray is credited with finding that electrical conductors must be insulated and that insulators were not conductors and that a charge could be induced in a previously non-electrified body. He established electricity as a current showing it would travel over a conductor. Gray found water to be a conductor which rendered insulators into conductors when their surfaces were wetted. This concept helps us to understand the rapid loss of charges on humid days by electrified bodies. He sent many of his papers to the Royal Society and was elected a fellow. He continued his research until upon his death bed he tried to describe to his doctor the work he still needed to complete.”

Insulators are material that inhibits the flow of electrical currents. The opposite of conductors, which allow electric particles to flow freely, insulators are implemented in household items and electrical circuits as protection. Thermal insulation is similar, but it constricts the flow of heat rather than electricity.

Insulator possesses a high resistivity and low conductivity. Their atoms tightly bound electrons that do not move throughout the material. Because the electrons are static and not freely roaming, a current cannot easily pass. In addition to protecting loss of current, insulators make an electrical current more efficient by concentrating the flow.

Prosperities of insulating material:

- It must be mechanically strong enough to carry tension and weight of conductors.

- It must have very high dielectric strength to withstand the voltage stresses in High Voltage system.

- It must possess high Insulation Resistance to prevent leakage current to the earth.

- The insulating material must be free from unwanted impurities.

- It should not be porous.

- There must not be any entrance on the surface of electrical insulator so that the moisture or gases can enter in it.

- There physical as well as electrical properties must be less affected by changing temperature.

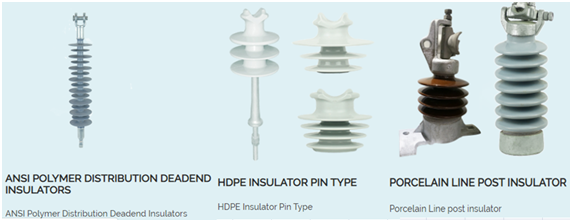

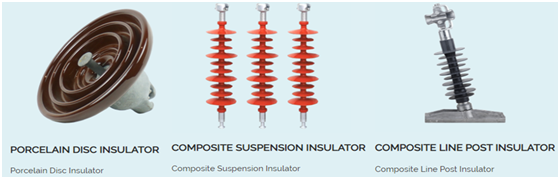

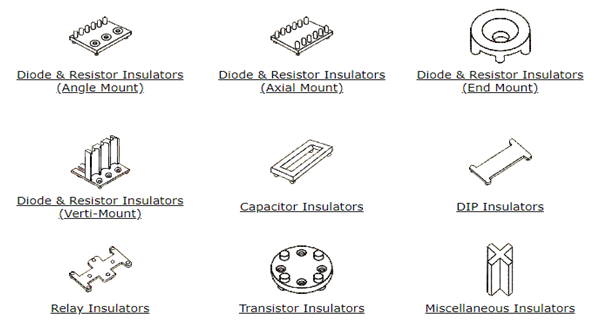

Types of insulators:

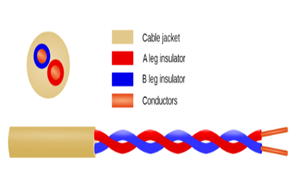

Conductors:

Conductors are the materials or substances which allow electricity to flow through them. They are able to conduct electricity because they allow electrons to flow inside them very easily. Conductors have this property of allowing the transition of heat or light from one source to another. Metals, humans, earth, and animal bodies are all conductors. This is the reason we get electric shocks! The main reason is that being a good conductor, our human body allows a resistance-free path for the current to flow from wire to our body. Conductors have free electrons on its surface which allows current to pass through. This is the reason why conductors are able to conduct electricity.

Definition of conductor:

A conductor is a wire or a group of wires which allow the current pass through its body. The conductor can be produced by single or multi wire process. The multi wire process gives a product commonly called “kock”. The various types of conductors but most simple conductor is the round wire. It shows the greater metallic section with smallest outside diameter. But its flexibility, its ability to be shaped, is generally insufficient for many users. So, conductors composed of wire with same diameter assembled together are preferred. These conductors have various configurations and the use confirmed the following classification:

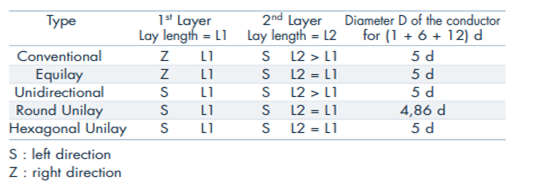

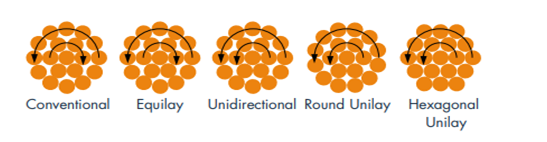

Concentric stranded conductors:

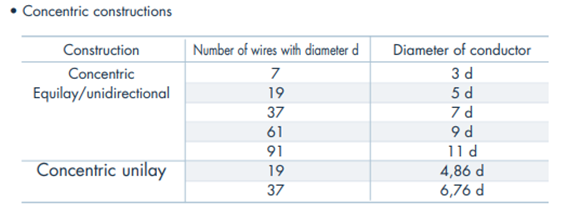

These conductors are composed of a central wire surrounded by one or several adjacent layers of wires being laid helically. The central wire is always the same and the wires layers are distinct and concentric. For the conductor having only one wire diameter the classic construction is: 1+6+12+18+etc…., the layer n+1 included 6 wires more than the layers n. Inside.

Inside this group, it is possible to establish 5 types of concentric stranded conductors:

Bunched Conductors: The bunched conductors are composed of wires assembled together helically, in same direction and with the same lay, without forming definite layers. On principle, a bunched conductor cannot be as round as a centric stranded conductor.

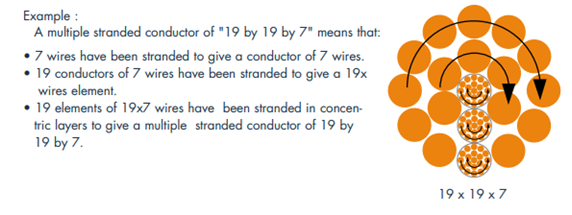

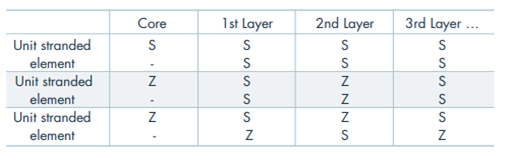

Multiple stranded conductors: Multiple stranded conductors are conductors composed of several stranded or bunched conductors assembled in one or several layers. These conductors have the same lay. The ASTM standards distinguish the conductor produced from concentric stranded conductors (ASTM B173) from the conductor produced from bunched conductors (ASTM B172). The arrangements of these conductors are defined according to the lay direction of the basic stranded and bunched conductors. The designation of these conductors uses the method proposed in the ASTM standard, you have to describe:

- In a first step the numbers of components which make up the multiple stranded conductor.7, 19, 37 or 61.

- After, separated by the word “by”, the number of components assembled from concentric stranded or bunched conductors.

Finally, separated by the word “by”, the number of wires which constitute the basic concentric stranded or bunched conductor.

So this conductor is composed of 2527 wires. The lay direction of the different elements could be different of this of the basic element or the upper element, as how above in the table.

Main characteristics of the conductor:

- Its diameter.

- Its linear resistance.

- Its linear mass.

They are necessary to calculate the dimensions of the conductor and its nominal intensity. Its ability to be shaped and its flexibility are determined by the composition.

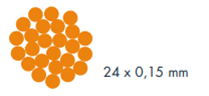

Diameter: The diameter is depending on the wires diameter. This is not sufficient because the wires arrangement has an effect too. Therefore it is necessary to classify firstly the several arrangements seen previously. The concentric arrangement allows an easy determination of the diameter while the bunched compositions need the use of empiric formulas with an uncertain reliability.

• Bunched and multiple stranded constructions the calculation of the diameter is more uncertain because depending largely on the cabling method, and the art of the cable manufacturer, etc… It exists an empiric formula to use with care but it gives an idea:

D = Kd. √N with

- D: average conductor diameter in mm.

- d: single wire diameter in mm.

- N: total number of wires.

- K: 1, 13 for bunched, 1, 18 for the multiple stranded conductors.

Linear electric resistance:

This property is the starting point of the choice of the conductor because it determines the carrying capacity of the conductor. It mainly depends on metal or alloy, of metallurgical state and of the presence of a coating. The nominal resistance of the various materials used in the conductors:

(a) Metallurgical state: The annealed material shows the minimum electrical resistivity. The hard worked material increases the resistivity due to mechanical deformations induced in the structure.

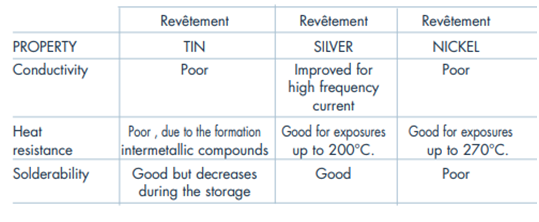

(b) Coated material: In order to improve some properties, some metal could be plated with another material showing properties suitable for some precise goal. For instance:

- Tin on copper in order to improve the solder ability, the corrosion resistance, and inertness with insulating materials.

- Silver on copper to improve the electrical conductivity for high frequency current, the solder ability and the resistance at high temperature during the heating of special insulating materials.

- Nickel on copper and on aluminum to improve the resistance of the copper at high temperature and the contact resistance of aluminum. Except to silver, the other materials, tin and nickel, increase the resistance and this fact shall be taken into account to calculate the linear resistance.

(c) Configuration of the conductor:

The electrical resistance of a material is proportional to its length and inversely proportional to its section. The cabling has the same influence on the resistance as on the linear mass due to the over length of the stranded wires. Therefore, the coefficients given for the linear mass calculation are the same for the calculation of the electrical resistance. Some formulas exist which take into account these three factors and this one for copper conductor is extracted from NFC 31.111 standard.

Linear mass:

The wires are helically assembled and therefore there is an over length which increases the linear mass of the conductor. This over length depends on the lay length used: the shorter the lay length is, the higher is the over length. The following figure indicates the helix properties to take into account for the calculations:

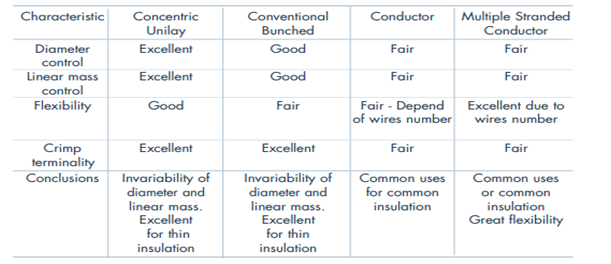

QUALITIES AND DEFECTS OF THE VARIOUS ARRANGEMENTS

In addition to the diameter and the linear resistance, the user shall estimate a lot of criteria’s for the choice of a type of conductor. The following table summarizes some main properties of the conductors according to their various uses.